Special Price for Lyophilized royal jelly powder in Marseille

Special Price for Lyophilized royal jelly powder in Marseille Detail:

[Products Name] Royal jelly powder,Lyophilized royal jelly powder

[Specification] 10-HDA 4.0%, 5.0%, 6.0%, HPLC

[Gerneral feature]

1. Low antibiotics, Chloramphenicol< 0.1ppb

2.Organic certified by ECOCERT, according to EOS & NOP organic standard;

3.100% pure with no additives;

4. More easily absorbed into the body than fresh royal jelly

5. Can be easily produced into tablets.

[Our advantages]

- 600 bee farmers, 150 units of bee-feeding groups located in natural mountains;

- Organic certificated by ECOCERT;

- NON-antibiotics, widely exported to Europe;

- Health Certificate, Sanitary Certificate and Quality Certificate are available.

[Lyophilized technology]

Lyophilized technology, also known as Freeze-drying, it is a dehydration process typically used to maintain activity of all nutrition ingredients in royal jelly, also to make the royal jelly convenient for transport. Freeze-drying works by freezing the material and then reducing the surrounding pressure to allow the frozen water in the material to sublimate directly from the solid phase to the gas phase. This technology can maintain all activity of nutrition ingredient.

Lyophilized royal jelly powder is processed directly from fresh royal jelly.

3kgs fresh royal jelly is used to make 1kg lyophilized royal jelly powder.

During all the production process, there is no additives.

[Packing]

5kg/bag, 25kgs/drum

1kg/bag, 20kgs/carton

Main indices of physical and chemic in Lyophilized royal jelly

| Ingredients Indices | Lyophilized royal jelly | Standards | Results |

| Ash | 3.2 | <5 | Complies |

| Water | 4.1% | <7% | Complies |

| Glucose | 43.9% | <50% | Complies |

| Protein | 38.29% | >33% | Complies |

| 10-HDA | 6.19% | >4.2% | Complies |

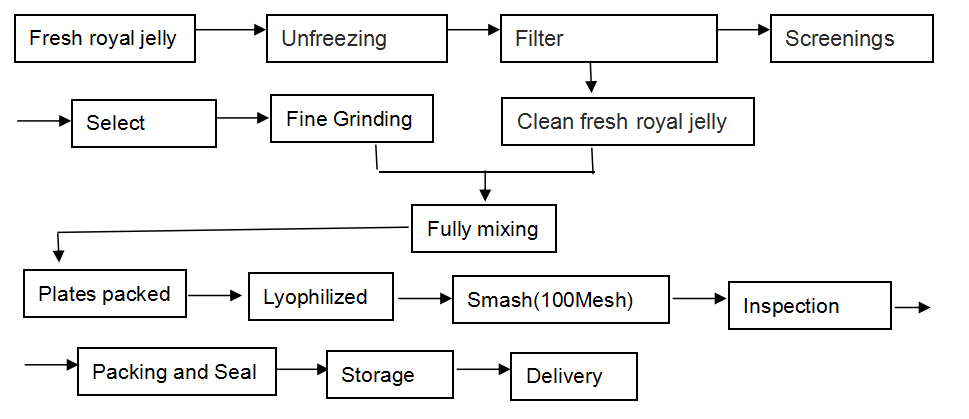

[Our work flow]

Our Lyophilized Royal Jelly Powder is produced in this way: we lyophilize the fresh royal jelly by advanced freeze-drying facilities without losing any nutritional ingredients, reserving the natural ingredients in utmost, and then make them into the form of powder, for any food additives are not needed to add.

The raw material we use is the natural fresh royal jelly which is up to the export standard . We process our products strictly according to export standard. Our workshop is up to the requirements of GMP.

Royal Jelly powder has been selected as drug excipients by many European and American pharmaceutical producing enterprises.Meanwhile it is applies to health food and cosmetics industries.

[Quality control]

Traceability record

GMP standard production

Advanced inspection equipment

[Function]

1.Enhances the immune system

2.Promotes wound healing

3.Has antitumor/anticancer properties

4.Lowers cholesterol levels

5.Increases fat metabolism

6.Is a powerful antioxidant

7.Regulates blood sugar levels

[Applications]

It’s widely used in health tonic, health pharmacy, hairdressing and cosmetic area, and mainly was applied in capsules, troche and oral liquids etc.

Product detail pictures:

Related Product Guide:

We support our purchasers with ideal high-quality merchandise and significant level company. Becoming the specialist manufacturer in this sector, we now have received loaded practical encounter in producing and managing for Special Price for Lyophilized royal jelly powder in Marseille , The product will supply to all over the world, such as: Malawi, Wellington, Auckland, we sincerely hope to establish a good and long-term business relationship with your esteemed company through this opportunity, based on equality, mutual benefit and win-win business from now to the future. "Your satisfaction is our happiness".

According to Wikipedia there are 17 types of green tea! Check out our healthy enzo organic matcha at https://yo.urenzo.com/product-category/matcha/ | Here at Enzo we have many new informational and fact videos about Green Tea and Matcha

More about Green tea on Wiki https://www.youtube.com/watch?v=cnOw0qfxc_Q

Sencha (煎茶, decocted tea)

1st and 2nd flushes of green tea made from leaves grown in sunlight.

This is the most common green tea in Japan.

Fukamushicha (深蒸し茶, long-steamed green tea)

Steamed two times longer than usual Sencha, giving it a deeper color and fuller flavor

Gyokuro (玉露, Jade Dew)

is grown under the shade rather than the full sun for approximately 20 days

Kabusecha (冠茶, covered tea)

Leafs grown in the shade prior to harvest not for as long as Gyokuro

Tamaryokucha (玉緑茶, lit. ball green tea)

Sungrown, picked, and placed in a revolving drum and dried with hot air.

Bancha (番茶, coarse tea)

Lower grade of Sencha harvested as a 3rd- or 4tg-flush tea between summer and autumn.

Kamairicha (窯煎茶, pan-fired tea)

Pan-fired green tea that does not undergo the usual steam treatments of Japanese tea

Other By-products of Sencha or Gyokuro

Kukicha (くき茶, stalk tea)

A tea made from stems, stalks, and twigs. It has a mildly nutty, and slightly creamy sweet flavor.

Mecha (芽茶, buds and tips tea)

Green tea derived from a collection of leaf buds and tips of the early crops

Konacha (粉茶, (coarse) powdered tea)

The dust and smallest parts after processing Gyokuro or Sencha

Tencha (ja) (碾茶, milling tea)

Like gyokuro, it is cultivated in shade, it has a sweet aroma

Matcha (抹茶, powdered tea)

A fine ground tea powder made from Tencha.

Genmaicha (玄米茶, brown rice tea)

Bancha (sometimes Sencha) and roasted genmai (brown rice) blend.

Hōjicha (ほうじ茶, roasted tea)

A green tea roasted over charcoal (usually Bancha).

Aracha (荒茶, raw green tea)

Half-finished products used for Sencha and Gyokuro production. It contains all parts of the plant.

Shincha (新茶, a new tea)

First flush tea. The name is used for either Sencha or Gyokuro.

Funmatsucha (粉末茶, instant powdered tea)

Milled green tea, used just like instant coffee. Aka “tokeru ocha,” or “tea that melts.”

#typesofgreentea

#newfactaday

#typeofgreentea

#greenteatypes

https://en.wikipedia.org/wiki/Matcha

Any questions,feel free to contact me.

Email:sales@chinesepacker.com Skype:zhang.tracy6

https://www.chinesepacker.com

Chick here to subscribe us

https://www.youtube.com/channel/UCZO2zKOPk7OImW9HZQpsp6A

Specifications

1. Automatic Soft Gelatin Encapsulation Machine

2. Injector save 20% gelatin

3. Hi-speed

4. Hi-precision, max. to +/-0.5%

Soft capsule making machine is used for making the soft capsules such as the fish oil soft capsules, vitamin E soft, Omega-3, and nutricfood capsule etc.

Use:

1. Softgel encapsulation machine can contolling and precisionally inject the oil,mixing suspension and pasty mass into the capsule to form all kinds of softgel encapsulation with different size,shape and color.

2.Owing to the high productivity,charging exactly,quality stabilization,high finished product rate,it is favoured by more and more manufacturers and used in the fields of medicine,health products,cosmetic and game-colour ball,etc.

Feature of The Machine:

Water-bath Injector, the temperature fluctuated in +/-0.1°C,save 14% gelatin; improve 1.5% rate of finished products; and save the maintained cost and time.

Computer control the plunger pump, improve the precision of medicine injection volume, and save more medicine and material cost.

The holes of the left and right main axis are processed with extreme accuracy on the boring machine imported from Switzerland. Though the mould roll has been extended in length, can be keep high coaxial degree that guarantees the smooth seam and finished product rate of the softgel capsule.

Bigger cam drive plunger pump, can provide stronger to plunger pump. That make the machine can inject widely high viscosity of raw material, such as Suspension, Propolis (Bee glue), Soft phospholipids, Liquid calcium and Herbal suspension.

Friendly human-computer interface, easy to operated. The simulated running of machine. The data can be set via touch screem, and easy to realizes network monitoring, statistics and reports output.

High quality and intelligence control system, PLC true color touch screen technology adopted by the electronic control system. All electric parts use world brand parts, such as Siemens, Schneider.

Professional PID temperature control technology is adopted on the machine, temperature of injector can be adjusted accurately. Improves ratio of finished products of soft gelatin capsule.

The touch screen provides professional ” recipe” function that can save the production paramters and recall them by one key.

The micro-lubrication device, can be adjust lubrication volume in fine volume, save cost.

Pneumatic clamping system makes capsule filling process more simple and reliable.

Motor hoisting injector can be fine located position as requirement, and reduce the workload of operator.

Speed of each gelatin film drum and main axis can be adjusted respectively by respectively invertor; that is controlled by operator according to actually requirement.

The opening of gelatin box is controlled accurately, the gauge showed gelatin film thickness. Easy to control the thickness.

Automatic controlled water-cooling system is adopted for the cooling of gelatin film, which is more safety and more reliable.

Air-cooling system is adopted at the output of softgelcapsule, that make softgel capsule more beautiful.

Insulation hopper, can keep medicine temperature steady, more suit to fill suspension into the softgel capsules.

Technical Data:

Mould Size (mm)

Dia. 150 X W: 250

Mould Revolution: (RPM)

0-5 Rpm (adjusted variable speed)

Volume of Plunger Pump

0-2 ml (adjustable continuously)

Pump Accuracy:

+/- 1.5%;

+/-0.5% (filling volume not less than 500 mg)

Pump Type

20 plunger pump

Production Capacity : (8# OV capsule)

115,440 pills/hrs(4.0 RPM)

(20# OB capsule)

58,800 (4.0 RPM)

Power Supply:

12 Kw, 360V 3 phases (can be modified as user’s requirement.)

Weight:

1,500 Kgs

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.