Professional Design Lyophilized royal jelly powder Supply to Jersey

Professional Design Lyophilized royal jelly powder Supply to Jersey Detail:

[Products Name] Royal jelly powder,Lyophilized royal jelly powder

[Specification] 10-HDA 4.0%, 5.0%, 6.0%, HPLC

[Gerneral feature]

1. Low antibiotics, Chloramphenicol< 0.1ppb

2.Organic certified by ECOCERT, according to EOS & NOP organic standard;

3.100% pure with no additives;

4. More easily absorbed into the body than fresh royal jelly

5. Can be easily produced into tablets.

[Our advantages]

- 600 bee farmers, 150 units of bee-feeding groups located in natural mountains;

- Organic certificated by ECOCERT;

- NON-antibiotics, widely exported to Europe;

- Health Certificate, Sanitary Certificate and Quality Certificate are available.

[Lyophilized technology]

Lyophilized technology, also known as Freeze-drying, it is a dehydration process typically used to maintain activity of all nutrition ingredients in royal jelly, also to make the royal jelly convenient for transport. Freeze-drying works by freezing the material and then reducing the surrounding pressure to allow the frozen water in the material to sublimate directly from the solid phase to the gas phase. This technology can maintain all activity of nutrition ingredient.

Lyophilized royal jelly powder is processed directly from fresh royal jelly.

3kgs fresh royal jelly is used to make 1kg lyophilized royal jelly powder.

During all the production process, there is no additives.

[Packing]

5kg/bag, 25kgs/drum

1kg/bag, 20kgs/carton

Main indices of physical and chemic in Lyophilized royal jelly

| Ingredients Indices | Lyophilized royal jelly | Standards | Results |

| Ash | 3.2 | <5 | Complies |

| Water | 4.1% | <7% | Complies |

| Glucose | 43.9% | <50% | Complies |

| Protein | 38.29% | >33% | Complies |

| 10-HDA | 6.19% | >4.2% | Complies |

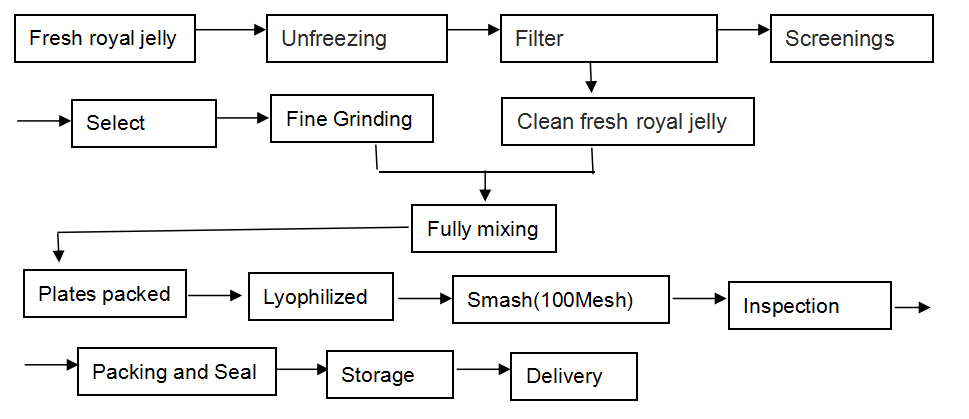

[Our work flow]

Our Lyophilized Royal Jelly Powder is produced in this way: we lyophilize the fresh royal jelly by advanced freeze-drying facilities without losing any nutritional ingredients, reserving the natural ingredients in utmost, and then make them into the form of powder, for any food additives are not needed to add.

The raw material we use is the natural fresh royal jelly which is up to the export standard . We process our products strictly according to export standard. Our workshop is up to the requirements of GMP.

Royal Jelly powder has been selected as drug excipients by many European and American pharmaceutical producing enterprises.Meanwhile it is applies to health food and cosmetics industries.

[Quality control]

Traceability record

GMP standard production

Advanced inspection equipment

[Function]

1.Enhances the immune system

2.Promotes wound healing

3.Has antitumor/anticancer properties

4.Lowers cholesterol levels

5.Increases fat metabolism

6.Is a powerful antioxidant

7.Regulates blood sugar levels

[Applications]

It’s widely used in health tonic, health pharmacy, hairdressing and cosmetic area, and mainly was applied in capsules, troche and oral liquids etc.

Product detail pictures:

Related Product Guide:

Our firm aims to operating faithfully, serving to all of our consumers , and working in new technology and new machine continually for Professional Design Lyophilized royal jelly powder Supply to Jersey , The product will supply to all over the world, such as: New York, Burundi, kazan, Selling our products and solutions causes no risks and brings high returns to your company instead. It is our consistent pursuit to create value for clients. Our company is looking for agents sincerely. What are you waiting for? Come and join us. Now or never.

Isotonix OPC-3® is an isotonic-capable food supplement that is made from a combination of bilberry, grape seed, red wine and pine bark extracts, and citrus extract bioflavonoids, all found to be powerful antioxidants. Oligomeric proanthocyanidins (OPCs) are bioflavonoids (complex organic plant compounds) found in fruits, vegetables and certain tree barks that provide exceptional nutritional benefits to the human body. Studies have shown OPCs to be up to 20 times more powerful than vitamin C and 50 times more powerful than vitamin E in neutralizing free radicals. Isotonix OPC-3 contains the only isotonic form of Pycnogenol® in the world. Pycnogenol is a natural plant extract from the bark of the French maritime pine tree and the most clinically researched and potent bioflavonoid.

Professor Maureen McCann, Director of the Energy Center at Purdue University, addresses “A Roadmap for Selective Deconstruction of Lignocellulosic Biomass to Advanced Biofuels and Useful Co-Products” on February 11, 2013 as part of the Andlinger Center’s 2012-2013 Highlight Seminar Series.

ABSTRACT

Second-generation biofuels will be derived from lignocellulosic biomass using biological catalysis to use the carbon in plant cell wall polysaccharides for ethanol or other biofuels. However, this scenario is both carbon- and energy-inefficient. The major components of biomass are cellulose, hemicellulose and lignin. Biological conversion routes utilize only the polysaccharide moiety of the wall, and the presence of lignin interferes with the access of hydrolytic enzymes to the polysaccharides. Living micro-organisms, required to ferment released sugars to biofuels, utilize some sugars in their own growth and co-produce carbon dioxide. In contrast, chemical catalysis has the potential to transform biomass components directly to alkanes, aromatics, and other useful molecules with improved efficiencies. The Center for Direct Catalytic Conversion of Biomass to Biofuels (C3Bio) is a DOE-funded Energy Frontier Research Center, comprising an interdisciplinary team of plant biologists, chemists and chemical engineers. We are developing catalytic processes to enable the extraction, fractionation, and depolymerization of cellulose and hemicellulose coupled to catalytic transformation of hexoses and pentoses into hydrocarbons. Additional catalysts may cleave the ether bonds of lignin to release useful aromatic co-products or that may oxidize lignols to quinones. In a parallel approach, fast-hydropyrolysis is a relatively simple and scalable thermal conversion process. Our understanding of biomass-catalyst interactions require novel imaging and analysis platforms, such as mass spectrometry to analyze potentially complex mixtures of reaction products and transmission electron tomography to image the effects of applying catalysts to biomass and to provide data for computational modeling. By integrating biology, chemistry and chemical engineering, our data indicate how we might modify cell wall composition, or incorporate Trojan horse catalysts, to tailor biomass for physical and chemical conversion processes. We envision a road forward for directed construction and selective deconstruction of plant biomass feedstock.

BIOGRAPHY

Maureen McCann is the Director of Purdue’s Energy Center, part of the Global Sustainability Initiative in Discovery Park. She obtained her undergraduate degree in Natural Sciences from the University of Cambridge, UK, in 1987, and then a PhD in Botany at the John Innes Centre, Norwich UK, a government-funded research institute for plant and microbial sciences. She stayed at the John Innes Centre for a post-doctoral, partly funded by Unilever, and then as a project leader with her own group from 1995, funded by The Royal Society. In January 2003, she moved to Purdue University as an Associate Professor, and she is currently a Professor in the Department of Biological Sciences.

The goal of her research is to understand how the molecular machinery of the plant cell wall contributes to cell growth and specialization, and thus to the final stature and form of plants. Plant cell walls are the source of lignocellulosic biomass, an untapped and sustainable resource for biofuels production with the potential to reduce oil dependence, improve national security, and boost rural economies. She is also the Director of the Center for Direct Catalytic Conversion of Biomass to Biofuels (C3Bio), an interdisciplinary team of biologists, chemists and chemical engineers in an Energy Frontier Research Center funded by the US Department of Energy’s Office of Science.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!