OEM/ODM China Sodium copper chlorophyllin Factory from Turin

OEM/ODM China Sodium copper chlorophyllin Factory from Turin Detail:

[Specification] 99%

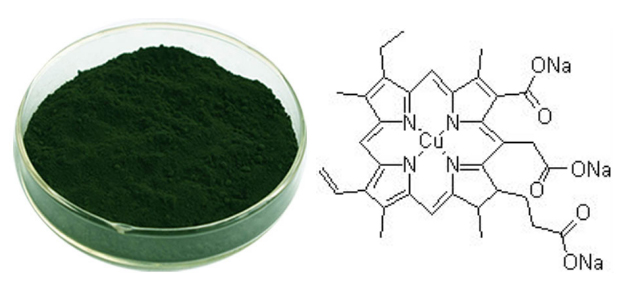

[Appearance] Dark Green powder

Plant Part Used:

[Particle size] 80Mesh

[Loss on drying] ≤5.0%

[Heavy Metal] ≤10PPM

[Storage] Store in cool & dry area, keep away from the direct light and heat.

[Shelf life] 24 Months

[Package] Packed in paper-drums and two plastic-bags inside.

[Net weight] 25kgs/drum

[What is that?]

Chlorophyll is a natural green pigment which is obtained through extraction and refining processes from natural green plants or silkworm feces.Chlorophyll is stabilized chlorophyll, which is prepared from chlorophyll by saponification and replacement of magnesium atom with copper and sodium. Chlorophyll is dark green to blue black powder, easily soluble in water but slightly soluble in alcohol and chloroform, with transparent jade green water solution without sediment.

[Function]

1.clears up odors of putrefaction effectively.

2.play an important role on cancer prevention.

3.Chlorophyll has superior coloring strength and good stabilization in neutral and alkali solutions.

4.Chlorophyll has effect on liver protection, fastening healing of stomach ulcers and intestine ulcers.

5.The active ingredient in a number of internally-taken preparations intended to reduce odors associated with incontinence, colostomies and similar procedures, as well as body odor in general.

6.Chlorophyll has strong antibacterial action, which makes it useful in surgeries, ulcerative carcinoma, acute rhinitis and rhinosinusitis, chronic ear infections, inflammations, etc.

Product detail pictures:

Related Product Guide:

Like a result of ours specialty and repair consciousness, our enterprise has won a superb popularity amid buyers everywhere in the environment for OEM/ODM China Sodium copper chlorophyllin Factory from Turin , The product will supply to all over the world, such as: Egypt, Pretoria, Liberia, We have a professional sales team, they have mastered the best technology and manufacturing processes, have years of experience in foreign trade sales, with customers able to communicate seamlessly and accurately understand the real needs of customers, providing customers with personalized service and unique products.

https://SuccesswithTroyandDana.com

Sugar Blocker | F21 All Natural Sugar Blocker | Ludaxx Sugar Blocker Works!

F21 has been specifically formulated as an All Natural Sugar Blocker™ to help limit your blood sugar absorption. For every tablet of F21 you can block up to 10 grams of sugar (sucrose). Additionally, our patent pending formula not only helps promote weight loss, it benefits the digestive system by allowing the blocked sucrose to support beneficial probiotic bacteria while the polysaccharide (PSK) boosts your immune system response.

F21 Ingredients:

L-Arabinose, Coriolus Versicolor Polysacchride, Konjac-Mannan, Magnesium Stearate

Mint flavor: Menthol and Natural Colors.

Dr Rudi’s Story

“As a medical weight loss specialist, I am so excited to have access to products that supports what I have been telling my patients for years at a cost that is affordable. One of the biggest problems my clients face is convincing them to make changes in their lifestyle before they start seeing success, now with F21 and the other Ludaxx products, changes can begin to happen even before their lifestyle has changed.”

What is F21?

F21 is a delicious tasting tablet that is half the sweetness of sugar which helps block sugar absorption into the bloodstream as well as supporting beneficial probiotics within your digestive system! It is also an antioxidant that will boost your immune system response…

Cameron’s Story

“I decided to join Ludaxx after I started seeing my friends and family that were using F21 begin to experience better health including weight loss. Even though the need to lose weight is not an issue that I am facing, knowing that every gram of F21 can block up to twenty grams of Sucrose makes me feel less worried that weight will ever be an issue for me.”

F21 has been formulated to help limit your blood sugar absorption and control further weight gain. For every gram of L-Arabinose, F21 blocks up to 20 grams of sugar (sucrose) by inhibiting the enzyme called sucrase. Our digestive system will also receive the benefits of F21 to feed probiotic bacteria. With our powerful polysaccharides (PSK) to support the immune system response and protect against further free radical damage, we present you the product of the future. *

* These statements have not been evaluated by the Food and Drug Administration (FDA). This product is not intended to diagnose, prevent, mitigate, treat or cure disease.

Ingredients

L-Arabinose, Coriolus versicolor polysaccharide,

Other Ingredients

Konjac-Mannan, Magnesium Stearate

Help us share the power of the F21 with others…

Thanks, Troy & Dana

904-591-5413

https://successwithtroyanddana.com

SUGAR BLOCKER

BLOCK SUGAR

LUDAXX SUGAR BLOCKER

LUDAXX F21

SUGAR BLOCKERS

[diabetes]

[glucose]

[diabetic diet]

[type 2 diabetes]

[blood sugar levels]

[glucose levels]

[low blood sugar]

[what is diabetes]

[normal blood sugar levels]

[low blood sugar symptoms]

[blood sugar]

[blood glucose levels]

[high blood sugar]

[normal blood sugar]

[blood sugar levels chart]

[symptoms of low blood sugar]

[high blood sugar symptoms]

[normal glucose levels]

[fasting blood sugar]

[blood sugar chart]

[symptoms of high blood sugar]

[blood glucose]

[normal blood glucose levels]

[how to lower blood sugar]

recyclage des opercules récupèrées lors du tirage du miel …en pain de cire !!!

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!