Hot sale good quality Lyophilized royal jelly powder Factory in Melbourne

Hot sale good quality Lyophilized royal jelly powder Factory in Melbourne Detail:

[Products Name] Royal jelly powder,Lyophilized royal jelly powder

[Specification] 10-HDA 4.0%, 5.0%, 6.0%, HPLC

[Gerneral feature]

1. Low antibiotics, Chloramphenicol< 0.1ppb

2.Organic certified by ECOCERT, according to EOS & NOP organic standard;

3.100% pure with no additives;

4. More easily absorbed into the body than fresh royal jelly

5. Can be easily produced into tablets.

[Our advantages]

- 600 bee farmers, 150 units of bee-feeding groups located in natural mountains;

- Organic certificated by ECOCERT;

- NON-antibiotics, widely exported to Europe;

- Health Certificate, Sanitary Certificate and Quality Certificate are available.

[Lyophilized technology]

Lyophilized technology, also known as Freeze-drying, it is a dehydration process typically used to maintain activity of all nutrition ingredients in royal jelly, also to make the royal jelly convenient for transport. Freeze-drying works by freezing the material and then reducing the surrounding pressure to allow the frozen water in the material to sublimate directly from the solid phase to the gas phase. This technology can maintain all activity of nutrition ingredient.

Lyophilized royal jelly powder is processed directly from fresh royal jelly.

3kgs fresh royal jelly is used to make 1kg lyophilized royal jelly powder.

During all the production process, there is no additives.

[Packing]

5kg/bag, 25kgs/drum

1kg/bag, 20kgs/carton

Main indices of physical and chemic in Lyophilized royal jelly

| Ingredients Indices | Lyophilized royal jelly | Standards | Results |

| Ash | 3.2 | <5 | Complies |

| Water | 4.1% | <7% | Complies |

| Glucose | 43.9% | <50% | Complies |

| Protein | 38.29% | >33% | Complies |

| 10-HDA | 6.19% | >4.2% | Complies |

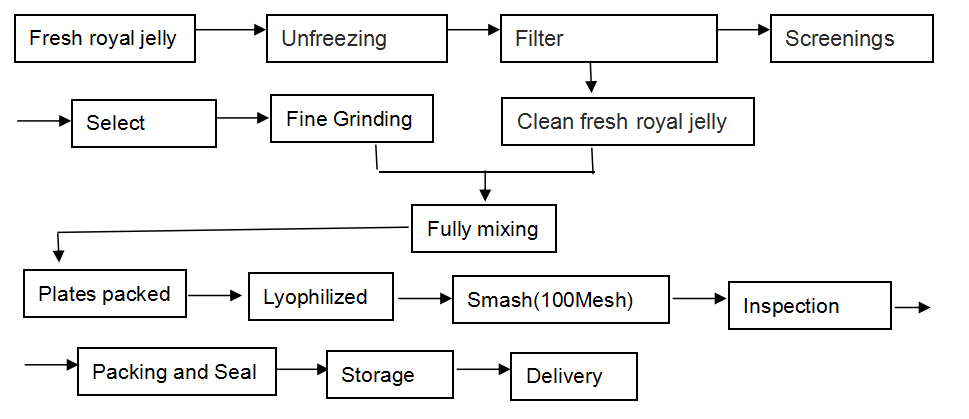

[Our work flow]

Our Lyophilized Royal Jelly Powder is produced in this way: we lyophilize the fresh royal jelly by advanced freeze-drying facilities without losing any nutritional ingredients, reserving the natural ingredients in utmost, and then make them into the form of powder, for any food additives are not needed to add.

The raw material we use is the natural fresh royal jelly which is up to the export standard . We process our products strictly according to export standard. Our workshop is up to the requirements of GMP.

Royal Jelly powder has been selected as drug excipients by many European and American pharmaceutical producing enterprises.Meanwhile it is applies to health food and cosmetics industries.

[Quality control]

Traceability record

GMP standard production

Advanced inspection equipment

[Function]

1.Enhances the immune system

2.Promotes wound healing

3.Has antitumor/anticancer properties

4.Lowers cholesterol levels

5.Increases fat metabolism

6.Is a powerful antioxidant

7.Regulates blood sugar levels

[Applications]

It’s widely used in health tonic, health pharmacy, hairdressing and cosmetic area, and mainly was applied in capsules, troche and oral liquids etc.

Product detail pictures:

Related Product Guide:

Our team through professional training. Skilled professional knowledge, strong sense of service, to meet the service needs of customers for Hot sale good quality Lyophilized royal jelly powder Factory in Melbourne , The product will supply to all over the world, such as: Swansea, Saudi Arabia, Italy, Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements. We can provided good quality with competitive price for you.

1.The Chilli Powder Line can treatment of chilli raw material 1500kgs, processing chilli powder:800-1200kgs, Size:50-60mesh.

2. Equipment should be installed in the flat and hard ground.

3.The equipment shall be strictly in accordance with the standards for the installation of electrical equipment, and reliable grounding.

4. Equipment before use, should check the lubrication part of the equipment required to fill the oil tank in the appropriate amount of oil.And also check the various parts, fasteners are loose in the way of transportation .

5. Products in a long time without the circumstances, to be stored in a dry, non corrosive gas environment, do not contact with the corrosion, so as to avoid damage to the machine.

6. Equipment installation is completed, before the test, should be separately to test the relevant equipment, so that after the normal operation, and then combined operation.

How to properly harvest and dry your herbs. We use Stevia in this video.

https://www.growingherbsforbeginners.com

This supplier offers high quality but low price products, it is really a nice manufacturer and business partner.