Hot Sale for Lyophilized royal jelly powder USA

Hot Sale for Lyophilized royal jelly powder USA Detail:

[Products Name] Royal jelly powder,Lyophilized royal jelly powder

[Specification] 10-HDA 4.0%, 5.0%, 6.0%, HPLC

[Gerneral feature]

1. Low antibiotics, Chloramphenicol< 0.1ppb

2.Organic certified by ECOCERT, according to EOS & NOP organic standard;

3.100% pure with no additives;

4. More easily absorbed into the body than fresh royal jelly

5. Can be easily produced into tablets.

[Our advantages]

- 600 bee farmers, 150 units of bee-feeding groups located in natural mountains;

- Organic certificated by ECOCERT;

- NON-antibiotics, widely exported to Europe;

- Health Certificate, Sanitary Certificate and Quality Certificate are available.

[Lyophilized technology]

Lyophilized technology, also known as Freeze-drying, it is a dehydration process typically used to maintain activity of all nutrition ingredients in royal jelly, also to make the royal jelly convenient for transport. Freeze-drying works by freezing the material and then reducing the surrounding pressure to allow the frozen water in the material to sublimate directly from the solid phase to the gas phase. This technology can maintain all activity of nutrition ingredient.

Lyophilized royal jelly powder is processed directly from fresh royal jelly.

3kgs fresh royal jelly is used to make 1kg lyophilized royal jelly powder.

During all the production process, there is no additives.

[Packing]

5kg/bag, 25kgs/drum

1kg/bag, 20kgs/carton

Main indices of physical and chemic in Lyophilized royal jelly

| Ingredients Indices | Lyophilized royal jelly | Standards | Results |

| Ash | 3.2 | <5 | Complies |

| Water | 4.1% | <7% | Complies |

| Glucose | 43.9% | <50% | Complies |

| Protein | 38.29% | >33% | Complies |

| 10-HDA | 6.19% | >4.2% | Complies |

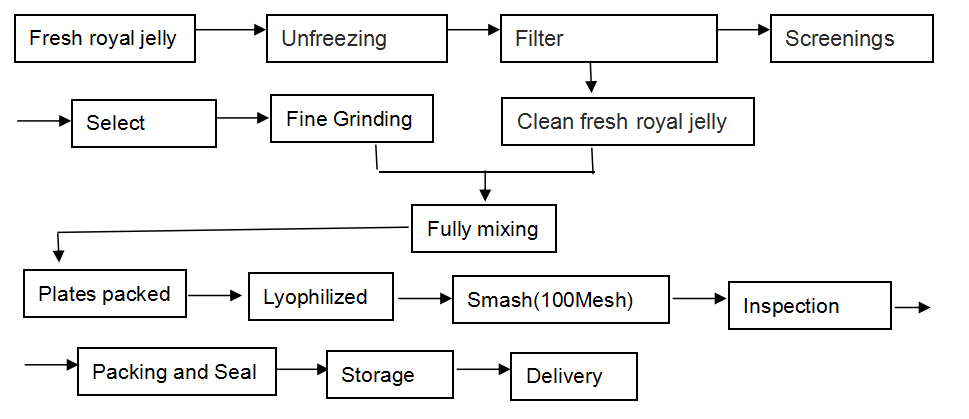

[Our work flow]

Our Lyophilized Royal Jelly Powder is produced in this way: we lyophilize the fresh royal jelly by advanced freeze-drying facilities without losing any nutritional ingredients, reserving the natural ingredients in utmost, and then make them into the form of powder, for any food additives are not needed to add.

The raw material we use is the natural fresh royal jelly which is up to the export standard . We process our products strictly according to export standard. Our workshop is up to the requirements of GMP.

Royal Jelly powder has been selected as drug excipients by many European and American pharmaceutical producing enterprises.Meanwhile it is applies to health food and cosmetics industries.

[Quality control]

Traceability record

GMP standard production

Advanced inspection equipment

[Function]

1.Enhances the immune system

2.Promotes wound healing

3.Has antitumor/anticancer properties

4.Lowers cholesterol levels

5.Increases fat metabolism

6.Is a powerful antioxidant

7.Regulates blood sugar levels

[Applications]

It’s widely used in health tonic, health pharmacy, hairdressing and cosmetic area, and mainly was applied in capsules, troche and oral liquids etc.

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" may be the persistent conception of our organization to the long-term to build together with shoppers for mutual reciprocity and mutual advantage for Hot Sale for Lyophilized royal jelly powder USA , The product will supply to all over the world, such as: Nepal, Dominica, Netherlands, We expect to deliver merchandise and services to more users in global aftermarket markets; we launched our global branding strategy by providing our excellent products and solutions all over the world by virtue of our well reputed partners letting global users keep pace with technology innovation and achievements with us.

https://blueberry.ws

A new study from Japan indicates that an all natural food element extracted from Blueberry leaves suppresses the replication of the hepatitis C virus. If the virus ca not make more of itself then all you’d have to do is find a way to kill what’s there already.

https://alternativemedicinesolution.com/blueberry-extract/

https://lloydwright.org/messages/search/node/blueberry

Raw Vegan Cheese – How to make Vegan Raw Nut and/or Seed Cheese using acidophilus starter. Make a seed or nut cheese of your choice, or a blend of seeds and nuts.

Instructions for Almond Nut Cheese:

Do the first batch with only a small amount of almonds so that if it doesn’t turn out as you want it, it won’t be a great loss. The art of fermenting may take a little practice to get it right.

You will need:

Raw Almonds,

Acidophilus/lactobacillus

salt

clean water (preferrably distilled, filtered or boiled and then cooled to room temperature)

We use a vegan acidophillus powder, some people make their own by fermenting wheat in water for a few days and using that water called rejuvelac, but that can be dicey and unpredictable.

Soak raw almonds overnight and drain and rinse before blanching. (If you make almond milk you can use the strained solids to make nut cheese, almond milk is also best if you blanch the almonds).

To blanch the almonds pour hot water onto them, enough to cover them. This will loosen the skins and you can just pop them off by squeezing them. Use a small piece of napped cotton for grip if they don’t pop off that easy.

Blend (a high speed blender is the best for this) the almonds and about a half to one teaspoon of salt to each jarful with enough clean water that the batter will be liquid enough to blend.

Once it is blended into a smooth thick batter add 1/4 tsp of acidophillus/lactobaccillus powder and pulse for a few seconds.

Put this batter into clean jars with about 1/3 empty at the top to allow for expansion. Screw on the lid but do not tighten so that fermentation gases can be released.

Put these jars in a warm place, from 80 degrees to mid nineties Fahrenheit, no hotter. Mid eighties to ninety degrees is probably ideal.

Leave them for at least 4 hours then check to see if you see signs of fermentation. That will be tiny bubbles, and the batter will be firming up. If you remove the lid and smell, you should smell a pleasant yeasty smell. Remember to replace the lid straight away when testing. Depending upon temperature, they can be ready from 4-6 or more hours. The cooler the temperature the longer it will take.

Once the bubbles have populated the cheese at least 50% you can put them into room temperature and leave them for the rest of the day or overnight. (room temps of 55 to 70 degrees F). The cheese is ready when it is many tiny bubbles you can see through the glass and it has a pleasant smell and a delicious tang.

Once the cheese is done, tighten the lids and refrigerate. It will last a week or two in the fridge (and even longer depending on various factors). Some people even freeze it, but we haven’t. We have used this cheese in many ways.

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.