High Quality Blackcurrant Extract Factory from Sevilla

High Quality Blackcurrant Extract Factory from Sevilla Detail:

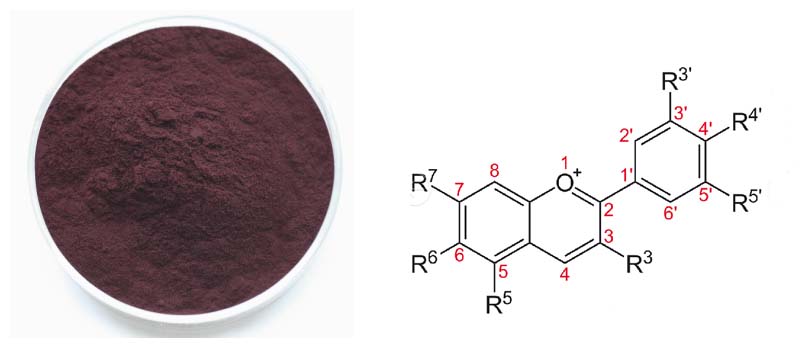

[Latin Name] Ribes nigrum

[Specification] Anthocyanosides≥25.0%

[Appearance] Purple black fine powder

Plant Part Used: Fruit

[Particle size] 80Mesh

[Loss on drying] ≤5.0%

[Heavy Metal] ≤10PPM

[Storage] Store in cool & dry area, keep away from the direct light and heat.

[Shelf life] 24 Months

[Package] Packed in paper-drums and two plastic-bags inside.

[Net weight] 25kgs/drum

[What is Black currant?]

The black currant bush is a 6-foot tall perennial that entered the world somewhere in the regions that include northern Asia and central and northern Europe. Its flowers display five reddish-green to brownish petals. The celebrated black currant fruit is a glossy-skinned berry that carries several seeds laden with marvelous nutritional and curative treasures. An established bush can produce ten pounds of fruit per season

[Benefits]

1. Vision help my eyesight

2. Urinary Tract Health

3. Ageing & Brain Function.

4. Natural Brain Boost

5. Digestion & Fighting Cancer

6. Reducing Erectile Dysfunction

Product detail pictures:

Related Product Guide:

We strive for excellence, service the customers", hopes to become the best cooperation team and dominator enterprise for personnel, suppliers and customers, realizes value share and continuous promotion for High Quality Blackcurrant Extract Factory from Sevilla , The product will supply to all over the world, such as: Chile, Chile, Greenland, We always adhere to follow the honesty, mutual benefit, common development, after years of development and the tireless efforts of all staff, now has perfect export system, diversified logistics solutions, comprehensive meet customer shipping, air transport, international express and logistics services. Elaborate one-stop sourcing platform for our customers!

Glucomannan Powder Packing Machine auger filler dust collector zippered pouch packer solution

Any questions,feel free to contact me.

Email: sales@chinesepacker.com Skype:zhang.tracy6 Tel:0086-13262514660

https://www.chinesepacker.com

Chick here to subscribe us

https://www.youtube.com/channel/UCo4XjYB_mRONyQKah8jbjVw

Function and characteristics

Easy to operate,adopt advanced PLC from Germany Siemens, mate with touch screen and electric control system, the man-machine interface is friendly.

Frequency conversion adjusts the speed: this machine uses frequency conversion equipment, can be adjusted within the range according to the needs of reality in production.

Automatic checking: no pouch or pouch open error, no fill, no seal. the bag can be used again, avoid wasting packing materials and raw materials.

Safty device: Machine stop at abnormal air pressure, heater disconnection alarm.

Horizontal conveyer style to giving bag: it can put on more bags on the bag storage and have a low requirement about the quality of bags.

Use the plastic bearing, don’t need put on oil, less pollution.

Use no oil vacuum pump, avoid polluting the environment in the production.

huff,clamp the meatus of bag when put the windpipe into it, then huff to open up the bag fully to bottom in oder to avoid the material overflow from the bag if the it is not opend fully

The packing materials loss low, what this machine is used the preformed bag, the bag pattern is perfect and has a high quality of the sealing part, this improved the product specification

Product or packing bag contact parts adopt stainless steel or other materials which accord with the food hygienic requirements, guarantee hygiene and security of the food

With different feeders changed to pack solid, liquid, thick liquid ,powder and so on.

The packing bag suits in extensive range, suit for multi-layer compound, monolayer PE , PP and so on Preformed bag made by film and paper.

Safty:

No bag – no filling- no sealing, machine alarm

Bag opening miss- no filling-no sealing, machine alarm

Machine stop or alarm when the air pressure is abnormal

Error position display at the control panel

Control panel locate on the right side top of the machineOutside of the machine and all the parts which touch

production all made by stainless steel.There are several safety doors made by aluminum Profile Frame.

The doors are equipped with safety proximity sensors Machine surface can be washed by water and brushed

by cloth.

Product Process

1.Giving bag

2.coding date

3.open bag

4.open zippered

5.filling &vibrate

6.sealing

7.double times sealing

8.forming & output packages.

Technique parameter:

Working position:six-working station/Eight-working station

Pouch material:Laminated filmPEPP etc.

Pouch pattern:Stand-up,spout,falt

Pouch size:W:100-210mm L:100-350mm

Speed:≤50pouches/min(The speed depends on the product status and filling weight))

Weight:1000KGS

Voltage:380V 3phase 50HZ/60HZ

Total power:2.5KW

Compress air:0.6m3/min(supply by user)

Our services:

A-The whole packing system

The Seller ensure the whole packing system can get to the requested capacity, accept and cooperate with the Buyer

to pass the final testing of the whole system.

B-On-site installation:

The Seller supply the on site installation for the whole packing system, but the fees including air tickets, foods, hotel

and translator in this period should be paid by User,the subsidy is 80USD/day.

B-Technical support

The Seller supplies the technical support of the whole use life of the system,including the vertical packing machine,

and theprocedures.

C-Spare parts supply

The Seller should supply the quick-wear parts with the machine, to help the Buyerin further using. In the quality

guarantee period, the Seller will supply the broken parts for free, except the easy worn parts or the damage is

caused by misoperation.After the guarantee period, the Seller will supply all the parts that the User need for the

whole use life of the machine in cost price.

หญ้าหวาน

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!