Good User Reputation for Sodium copper chlorophyllin Factory in Argentina

Good User Reputation for Sodium copper chlorophyllin Factory in Argentina Detail:

[Specification] 99%

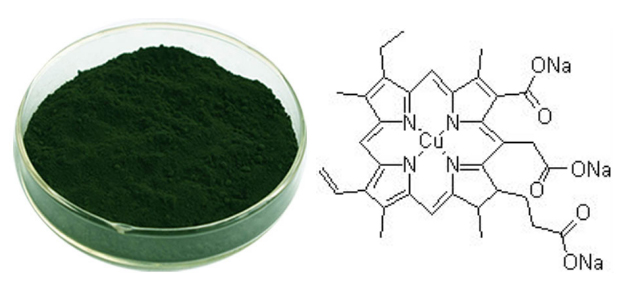

[Appearance] Dark Green powder

Plant Part Used:

[Particle size] 80Mesh

[Loss on drying] ≤5.0%

[Heavy Metal] ≤10PPM

[Storage] Store in cool & dry area, keep away from the direct light and heat.

[Shelf life] 24 Months

[Package] Packed in paper-drums and two plastic-bags inside.

[Net weight] 25kgs/drum

[What is that?]

Chlorophyll is a natural green pigment which is obtained through extraction and refining processes from natural green plants or silkworm feces.Chlorophyll is stabilized chlorophyll, which is prepared from chlorophyll by saponification and replacement of magnesium atom with copper and sodium. Chlorophyll is dark green to blue black powder, easily soluble in water but slightly soluble in alcohol and chloroform, with transparent jade green water solution without sediment.

[Function]

1.clears up odors of putrefaction effectively.

2.play an important role on cancer prevention.

3.Chlorophyll has superior coloring strength and good stabilization in neutral and alkali solutions.

4.Chlorophyll has effect on liver protection, fastening healing of stomach ulcers and intestine ulcers.

5.The active ingredient in a number of internally-taken preparations intended to reduce odors associated with incontinence, colostomies and similar procedures, as well as body odor in general.

6.Chlorophyll has strong antibacterial action, which makes it useful in surgeries, ulcerative carcinoma, acute rhinitis and rhinosinusitis, chronic ear infections, inflammations, etc.

Product detail pictures:

Related Product Guide:

Our well-equipped facilities and great good quality regulate throughout all stages of manufacturing enables us to guarantee total buyer gratification for Good User Reputation for Sodium copper chlorophyllin Factory in Argentina , The product will supply to all over the world, such as: Hungary, Lithuania, Bolivia, Our staffs are adhering to the "Integrity-based and Interactive Development" spirit, and the tenet of "First-class Quality with Excellent Service". According to the needs of every customer, we provide customized & personalized services to help customers achieve their goals successfully. Welcome clients from home and abroad to call and inquire!

Acupressure can improve your sex life by treating such common problems as infertility and impotence, using the big toe, liver-three, kidney-one and solar plexus foot points. Address your sexual issues in this free video on acupressure techniques.

Expert: Hillary Talbott

Bio: Hillary Talbott, a Doctor of Oriental medicine, practices at Acupuncture & Herbal Therapies in St. Petersburg, Florida.

Filmmaker: Christopher Rokosz

Series Description: Acupressure techniques apply pressure to specific trigger points on the body to increase overall health while treating issues ranging from infertility to sinus headaches. Get valuable tips on this ancient healing practice from a doctor of Oriental medicine in this free video series.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.