Good User Reputation for Lyophilized royal jelly powder Factory for Jersey

Good User Reputation for Lyophilized royal jelly powder Factory for Jersey Detail:

[Products Name] Royal jelly powder,Lyophilized royal jelly powder

[Specification] 10-HDA 4.0%, 5.0%, 6.0%, HPLC

[Gerneral feature]

1. Low antibiotics, Chloramphenicol< 0.1ppb

2.Organic certified by ECOCERT, according to EOS & NOP organic standard;

3.100% pure with no additives;

4. More easily absorbed into the body than fresh royal jelly

5. Can be easily produced into tablets.

[Our advantages]

- 600 bee farmers, 150 units of bee-feeding groups located in natural mountains;

- Organic certificated by ECOCERT;

- NON-antibiotics, widely exported to Europe;

- Health Certificate, Sanitary Certificate and Quality Certificate are available.

[Lyophilized technology]

Lyophilized technology, also known as Freeze-drying, it is a dehydration process typically used to maintain activity of all nutrition ingredients in royal jelly, also to make the royal jelly convenient for transport. Freeze-drying works by freezing the material and then reducing the surrounding pressure to allow the frozen water in the material to sublimate directly from the solid phase to the gas phase. This technology can maintain all activity of nutrition ingredient.

Lyophilized royal jelly powder is processed directly from fresh royal jelly.

3kgs fresh royal jelly is used to make 1kg lyophilized royal jelly powder.

During all the production process, there is no additives.

[Packing]

5kg/bag, 25kgs/drum

1kg/bag, 20kgs/carton

Main indices of physical and chemic in Lyophilized royal jelly

| Ingredients Indices | Lyophilized royal jelly | Standards | Results |

| Ash | 3.2 | <5 | Complies |

| Water | 4.1% | <7% | Complies |

| Glucose | 43.9% | <50% | Complies |

| Protein | 38.29% | >33% | Complies |

| 10-HDA | 6.19% | >4.2% | Complies |

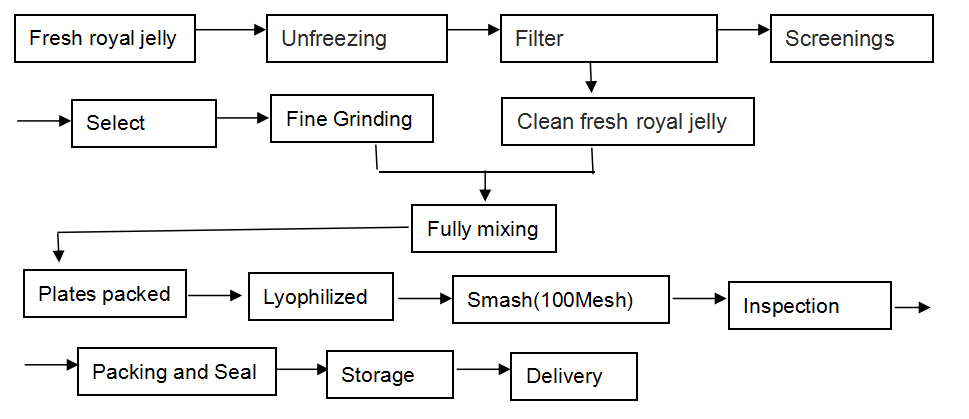

[Our work flow]

Our Lyophilized Royal Jelly Powder is produced in this way: we lyophilize the fresh royal jelly by advanced freeze-drying facilities without losing any nutritional ingredients, reserving the natural ingredients in utmost, and then make them into the form of powder, for any food additives are not needed to add.

The raw material we use is the natural fresh royal jelly which is up to the export standard . We process our products strictly according to export standard. Our workshop is up to the requirements of GMP.

Royal Jelly powder has been selected as drug excipients by many European and American pharmaceutical producing enterprises.Meanwhile it is applies to health food and cosmetics industries.

[Quality control]

Traceability record

GMP standard production

Advanced inspection equipment

[Function]

1.Enhances the immune system

2.Promotes wound healing

3.Has antitumor/anticancer properties

4.Lowers cholesterol levels

5.Increases fat metabolism

6.Is a powerful antioxidant

7.Regulates blood sugar levels

[Applications]

It’s widely used in health tonic, health pharmacy, hairdressing and cosmetic area, and mainly was applied in capsules, troche and oral liquids etc.

Product detail pictures:

Related Product Guide:

With our excellent administration, potent technical capability and strict top quality control technique, we go on to provide our consumers with trusted quality, reasonable price ranges and fantastic providers. We intention at becoming one among your most trusted partners and earning your fulfillment for Good User Reputation for Lyophilized royal jelly powder Factory for Jersey , The product will supply to all over the world, such as: Houston, Indonesia, Montpellier, With a fully integrated operation system, our company has won a good fame for our high quality goods, reasonable prices and good services. Meanwhile, we have established a strict quality management system conducted in material incoming, processing and delivery. Abiding by the principle of "Credit first and customer supremacy", we sincerely welcome clients from home and abroad to cooperate with us and advance together to create a brilliant future.

En Ucuz Nature’s Bounty Ürünleri

Nature,s Bounty ,nature’s bounty biotin, Nature’s Bounty calcium magnesium zinc, Nature’s Bounty ginseng complex, Nature’s Bounty l-carnitine, Nature’s Bounty omega 3, Nature’s Bounty ürünleri, Nature’s Bounty therm complex, Nature’s Bounty türkiye, Nature’s Bounty formula snh, Natures Bounty,natures bounty türkiye,natures bounty fish oil,natures bounty vitamin,natures bounty vitamins,natures bounty calcium,natures bounty codes,natures bounty jobs,natures bounty morganton nc,natures bounty coupons,

Nature’s Bounty ürünlerine en uygun fiyatlar ve ödeme koşulları ile https://www.dermobakim.com/Nature-s-Bounty_br_262 den satın alarak sahip olabilirsiniz

Nature’s Bounty Evening Primrose Oil 1000 mg 60 Soft jel https://www.dermobakim.com/Nature-s-Bounty-Evening-Primrose-Oil-1000-mg-60-Soft-jel_3220.html#0

Nature’s Bounty Biotin 5000 Mcg 60Kapsül https://www.dermobakim.com/Nature-s-Bounty-Biotin-5000-Mcg-60Kapsul_3228.html#0

Nature’s Bounty Ginseng Complex Plus Royal Jelly 75 Kapsül https://www.dermobakim.com/Nature-s-Bounty-Ginseng-Complex-Plus-Royal-Jelly-75-Kapsul_3213.html#0

Nature’s Bounty Chromium Picolinate 200 mcg 100 Tablet Nature’s Bounty Chromium Picolinate 200 mcg 100 Tablet

Nature’s Bounty Gentle Iron 28mg 90 Kapsül https://www.dermobakim.com/Nature-s-Bounty-Gentle-Iron-28mg-90-Kapsul_3215.html#0

Nature’s Bounty Folic Acid 400 mcg 100Tablet https://www.dermobakim.com/Nature-s-Bounty-Folic-Acid-400-mcg-100Tablet_3217.html#0

Nature’s Bounty L-Carnitine 500mg 30Kapsül https://www.dermobakim.com/Nature-s-Bounty-L-Carnitine-500mg-30Kapsul_3212.html#0

Nature’s Bounty Flush Free Niacin 500 mg 50Kapsül https://www.dermobakim.com/Nature-s-Bounty-Flush-Free-Niacin-500-mg-50Kapsul_3218.html#0

Nature’s Bounty Cla 1000 Mg 50 Soft jel https://www.dermobakim.com/Nature-s-Bounty-Cla-1000-Mg-50-Soft-jel_3222.html#0

Nature’s Bounty ThermComplex 60 Kapsül https://www.dermobakim.com/Nature-s-Bounty-ThermComplex-60-Kapsul_3206.html#0

Nature’s Bounty St. John,s Wort 300 Mg 100 Kapsül https://www.dermobakim.com/Nature-s-Bounty-St-John-s-Wort-300-Mg-100-Kapsul_3207.html#0

Nature’s Bounty Q-Sorb Co-Q10 100mg Plus 60 Softjel https://www.dermobakim.com/Nature-s-Bounty-Q-Sorb-Co-Q10-100mg-Plus-60-Softjel_3208.html#0

Nature’s Bounty Natural Selenium 200 mcg 50 Tablet https://www.dermobakim.com/Nature-s-Bounty-Natural-Selenium-200-mcg-50-Tablet_3209.html#0

Nature’s Bounty Multi-DayTM with Green Tea 50Tablet https://www.dermobakim.com/Nature-s-Bounty-Multi-DayTM-with-Green-Tea-50Tablet_3210.html#0

Nature’s Bounty Milk Thistle 175 mg 50Kapsül https://www.dermobakim.com/Nature-s-Bounty-Milk-Thistle-175-mg-50Kapsul_3211.html#0

Nature’s Bounty Ginkgo Biloba 60 Mg 60 Tablet https://www.dermobakim.com/Nature-s-Bounty-Ginkgo-Biloba-60-Mg-60-Tablet_3214.html#0

Nature’s Bounty Formula SNHTM 60Tablet https://www.dermobakim.com/Nature-s-Bounty-Formula-SNHTM-60Tablet_3216.html#0

Nature’s Bounty Fish Oil 1000 Mg 50Soft jel https://www.dermobakim.com/Nature-s-Bounty-Fish-Oil-1000-Mg-50Soft-jel_3219.html#0

Nature’s Bounty Echinacea Extract 30ml https://www.dermobakim.com/Nature-s-Bounty-Echinacea-Extract-30ml_3221.html#0

Nature’s Bounty Chelated Zinc 25 Mg 100Tablet https://www.dermobakim.com/Nature-s-Bounty-Chelated-Zinc-25-Mg-100Tablet_3224.html#0

Nature’s Bounty Oystercal Calcium 500mg 60 Tablet https://www.dermobakim.com/Nature-s-Bounty-Oystercal-Calcium-500mg-60-Tablet_3226.html#0

Nature’s Bounty Calcium 600 With Vitamin D3 60 Tablet https://www.dermobakim.com/Nature-s-Bounty-Calcium-600-With-Vitamin-D3-60-Tablet_3227.html#0

Nature’s Bounty Vitamin E-400 IU ( 100 Natural) 50Soft Jel https://www.dermobakim.com/Nature-s-Bounty-Vitamin-E-400-IU-100-Natural-50Soft-Jel_3229.html#0

Nature’s Bounty Calcium Magnesium Zinc 100 Tablet https://www.dermobakim.com/Nature-s-Bounty-Calcium-Magnesium-Zinc-100-Tablet_3225.html#0

Visit https://sunwarrior.com/

You’re in for a treat today. Jason Wrobel, the lovable celebrity chef, author, and television host, is in the hizzle to teach you how to boost your sex drive naturally! That’s right, J-Wro is all about the libido in this video. You’re welcome!

Apart from the obvious, enhancing your libido can have a host of other health benefits. More energy, better hormones, extra happiness, and improved heart health can all come from taking vitamins, supplements, and superfoods for libido. Start by getting more testosterone flowing through your blood stream. The best way to do this is to start lifting weights or doing bodyweight exercises. Weight-bearing, resistance movements increase your body’s production of this hormone. Selenium can also increase testosterone. You can find it in Brazil nuts, sunflower seeds, and mushrooms.

To put the “boom boom” back in the bedroom, you’ve gotta get some B complex vitamins. They enhance nerve function and energy levels. They also increase blood flow (nudge nudge wink wink). Speaking of blood flow, mainly the heart, you need magnesium. It’s the number one mineral in which people tend to be deficient. It is key to nerve function, heart health, and healthy blood in general. You want that blood healthy and pumping to all the right places. Vitamin E is also important. It increases circulation, sperm count, and sperm motility.

For superfoods to boost libido, Jason is a big fan of cacao, cinnamon, cranberry, maca, kabocha squash, pumpkin seeds, pomegranate, sea vegetables, and watermelon. Beyond that, J-Wro recommends meditation and sleep. High levels of stress and anxiety strangle your love life. Kill the cortisol, and enjoy your increased sex drive!

–

Subscribe to our channel: https://www.youtube.com/subscription_center?add_user=sunwarriortribe

–

For more health tips visit us at:

https://www.sunwarrior.com/healthhub

Like us on Facebook:

https://www.facebook.com/sunwarrior

Follow us on Instagram:

https://instagram.com/sunwarriortribe

Follow us on Twitter:

https://twitter.com/Sunwarrior

Hang out with us on Google+: https://plus.google.com/+Sunwarrior/posts

Follow us on Pinterest:

https://pinterest.com/sunwarriortribe/

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.