Chinese wholesale Blackcurrant Extract Manufacturer in Suriname

Chinese wholesale Blackcurrant Extract Manufacturer in Suriname Detail:

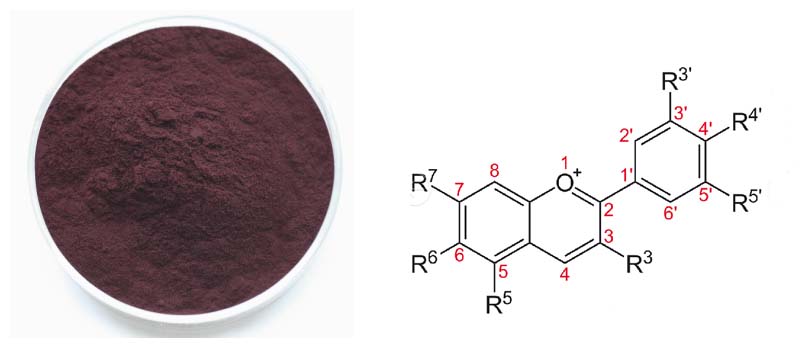

[Latin Name] Ribes nigrum

[Specification] Anthocyanosides≥25.0%

[Appearance] Purple black fine powder

Plant Part Used: Fruit

[Particle size] 80Mesh

[Loss on drying] ≤5.0%

[Heavy Metal] ≤10PPM

[Storage] Store in cool & dry area, keep away from the direct light and heat.

[Shelf life] 24 Months

[Package] Packed in paper-drums and two plastic-bags inside.

[Net weight] 25kgs/drum

[What is Black currant?]

The black currant bush is a 6-foot tall perennial that entered the world somewhere in the regions that include northern Asia and central and northern Europe. Its flowers display five reddish-green to brownish petals. The celebrated black currant fruit is a glossy-skinned berry that carries several seeds laden with marvelous nutritional and curative treasures. An established bush can produce ten pounds of fruit per season

[Benefits]

1. Vision help my eyesight

2. Urinary Tract Health

3. Ageing & Brain Function.

4. Natural Brain Boost

5. Digestion & Fighting Cancer

6. Reducing Erectile Dysfunction

Product detail pictures:

Related Product Guide:

We are experienced manufacturer. Wining the majority of the crucial certifications of its market for Chinese wholesale Blackcurrant Extract Manufacturer in Suriname , The product will supply to all over the world, such as: El Salvador, Turkey, belarus, we rely on own advantages to build a mutual-benefit commerce mechanism with our cooperative partners. As a result, we've gained a global sales network reaching the Middle East, Turkey, Malaysia and Vietnamese.

Rainstorm track with male enhancement subliminals. For adults 18+ only. The subliminal messages are in the audio only, so you don’t need to look at the video unless you want to. You can just sit back, relax your mind and listen to the audio at a normal volume. Speakers or headphones are both fine. You can also have it in the background while doing other activities. Once in the morning and once before bed is recommended, but the more you listen the more it will help. However, more than 12 hours a day of subliminals will tire your mind and be counterproductive.

You can find more details about the natural libido enhancement remedies at https://www.naturalwomenhealth.com/herbal-treatment-for-low-libido-in-women.htm

Dear friend, in this video we are going to discuss about the natural libido enhancement remedies. Women can come out of low libido problem with natural remedies like Lady Fire capsules.

If you liked this video, then please subscribe to our YouTube Channel to get updates of other useful health video tutorials.

Natural Libido Enhancement Remedies

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,