18 years Factory offer Green tea extract Supply to Poland

18 years Factory offer Green tea extract Supply to Poland Detail:

[Latin Name] Camellia sinensis

[Plant Source] China

[Specifications]

Total tea polyphenols 40%-98%

Total catechins 20%-90%

EGCG 8%-60%

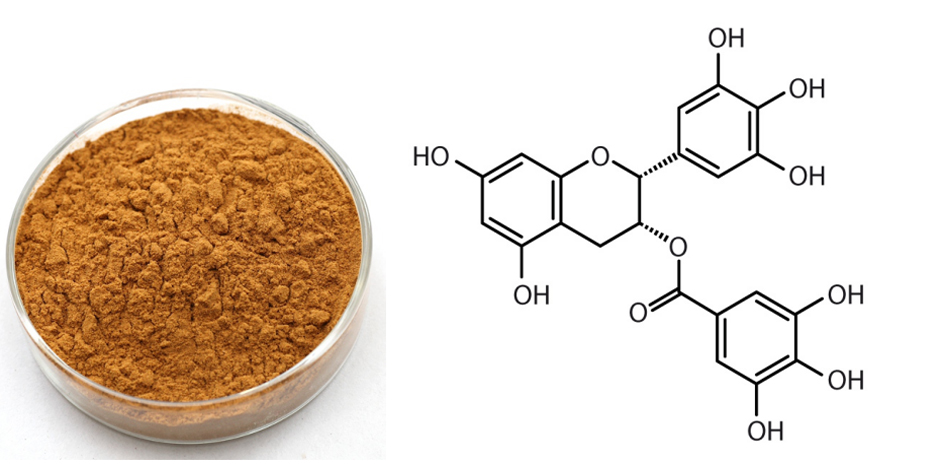

[Appearance] Yellow brown powder

[Plant Part Used] Green tea leaf

[Particle size] 80 Mesh

[Loss on drying] ≤5.0%

[Heavy Metal] ≤10PPM

[Storage] Store in cool & dry area, keep away from the direct light and heat.

[Package] Packed in paper-drums and two plastic-bags inside.

[What is green tea extract]

Green tea is the second largest beverage demanded by consumers worldwide. Used in China and India for its medicinal effects. There are several compounds extracted from green tea including catechins which contain an enormous amount of hydroxyphenols that are easily oxidized, congregated and contracted, which explains its good anti-oxidation effect. Its anti-oxidation effect is 25-100 times as strong as those of vitamin C and E.

It is widely used in medicines, agriculture, and chemical and food industries. This extract prevents cardio-vascular disease, lowers the risk of cancer, and decreases blood sugar and blood pressure, as well as viruses. In the food industry, the anti-oxidation agent used for preserving food and cooking oils.

[Function]

1. Green tea extract can reduce blood pressure, blood sugar, blood lipids.

2. Green tea extract has the function of removing radicals and anti-aging.

3. Green tea extract can enhance the immune function and prevention of colds.

4. Green tea extract will anti-radiation,anti-cancer, inhibiting the increasing of cancer cell.

5. Green tea extract used to anti-bacterium, with the function of sterilization and deodorization.

[Application]

1.Applied in cosmetics field, Green tea extract owns the effect of anti-wrinkle and anti-Aging.

2.Applied in food field, Green tea extract is used as natural antioxidant, antistaling agent, and anti-fading agents.

3.Applied in pharmaceutical field, Green tea extract is used to prevent and cure cardiovascular disease, diabetes.

Product detail pictures:

Related Product Guide:

We have a professional, efficiency team to provide quality service for our customer. We always follow the tenet of customer-oriented, details-focused for 18 years Factory offer Green tea extract Supply to Poland , The product will supply to all over the world, such as: Finland, America, Lebanon, With strong technical strength and advanced production equipment, and SMS people purposefully , professional, dedicated spirit of enterprise. Enterprises took the lead through the ISO 9001:2008 international quality management system certification, CE certification EU ; CCC.SGS.CQC other related product certification. We look forward to reactivating our company connection.

Video hecho por los alumnos del segundo nivel de inglés del Instituto Tecnológico del Valle de Oaxaca en convenio con la Facultad de Idiomas de la UABJO. El tema es el problema de la contaminación.

https://www.nutritionforest.com/eco-friendly-tea-extract.html

https://www.nutritionforest.com

Nutrition Forest Eco-friendly Tea Extract ninety eight% with 500mg

Eco-friendly tea belongs to Camellia Sinensis plant, an evergreen shrub whose leaves are applied to make tea. Eco-friendly tea is indigenous to china but now proliferated in numerous components of Asia. Steeping leaves into warm drinking water to put together eco-friendly tea for drink has promulgated due to its various invincible and remarkable rewards.

An easy stage of steeping leaves in warm drinking water to launch its taste and extract and then drink offers many rewards. Eco-friendly tea extract helps to lose excess weight. It supports immune program, inhibits cardiovascular condition and also helps to reduce tension and melancholy.

Eco-friendly tea extract includes flavonoids, offer electrical power to system. Flavonoids are antioxidants which inhibit cells injury by free radicals. Staying antioxidant and anti-inflammatory it also prevents cardiovascular condition.

Eco-friendly tea extract includes some sum of caffeine, a stimulant conducive to burn off excess fat and improves the purpose of metabolism. Most successful catechin in eco-friendly tea is EGCG which burns excess fat and controls huge sum of calories.

Why Eco-friendly Tea?

Eco-friendly tea has been applied as a drugs for countless numbers of several years, originating in China but extensively applied all over Asia this beverage has a multitude of uses from decreasing blood tension to avoiding cancer. The motive that eco-friendly tea has far more overall health rewards attached to it than black tea is (apparently) due to the processing. Black tea is processed in a way that enables for fermentation whereas eco-friendly tea’s processing avoids the fermentation approach. As a final result, eco-friendly tea retains maximum sum of antioxidants and poly-phenols the substances that give eco-friendly tea its numerous rewards.

Here’s a record of some of its awesome rewards — rewards that you may well not have been informed of. Some of these rewards are however currently being debated, so be sure to do your individual analysis if you want to use eco-friendly tea for medicinal reasons.

one. Pounds Reduction. Eco-friendly tea boosts the metabolism. The polyphenol discovered in eco-friendly tea operates to intensify levels of excess fat oxidation and the charge at which your system turns foodstuff into calories.

two. Diabetic issues. Eco-friendly tea apparently helps control glucose levels slowing the rise of blood sugar after having. This can protect against superior insulin spikes and ensuing excess fat storage.

three. Heart Disease. Researchers assume, eco-friendly tea operates on the lining of blood vessels, supporting retain them continue to be peaceful and superior capable to stand up to alterations in blood tension. It may well also defend versus the formation of clots, which are the primary lead to of coronary heart attacks.

four. Esophageal Cancer. It can reduce the chance of esophageal cancer, but it is also extensively assumed to eliminate cancer cells in typical without damaging the healthful tissue close to them.

five. Cholesterol. Eco-friendly tea decreases undesirable cholesterol in the blood and improves the ratio of fantastic cholesterol to undesirable cholesterol.

six. Alzheimer’s and Parkinson’s. It is reported to hold off the deterioration caused by Alzheimer’s and Parkinson’s. Scientific tests carried out on mice confirmed that eco-friendly tea guarded mind cells from dying and restored ruined mind cells.

seven. Tooth Decay. Scientific tests implies that the chemical antioxidant “catechin” in tea can demolish microbes and viruses that lead to throat infections, dental caries and other dental circumstances

eight. Blood Stress. Typical use of eco-friendly tea is assumed to reduce the chance of superior blood tension.

nine. Melancholy. Theanine is an amino acid by natural means discovered in tea leaves. It is this substance that is assumed to offer a enjoyable and tranquilizing influence and be a terrific gain to tea drinkers.

10. Anti-viral and Anti-bacterial. Tea catechins are strong antibacterial and antiviral agents which make them successful for managing everything from influenza to cancer. In some reports eco-friendly tea has been shown to inhibit the spread of numerous ailments.

11. Skincare. Eco-friendly tea can apparently also assist with wrinkles and the indications of getting old, This is because of their antioxidant and anti-inflammatory routines. The two animal and human reports have demonstrated that eco-friendly tea applied topically can reduce sun injury.

eco-friendly tea rewards

rewards of eco-friendly tea

eco-friendly tea extract

most effective eco-friendly tea

eco-friendly tea eating plan

eco-friendly tea powder

eco-friendly tea for excess weight reduction

matcha eco-friendly tea

gain of eco-friendly tea

organic and natural eco-friendly tea

matcha eco-friendly tea powder

what is eco-friendly tea

eco-friendly tea leaves

japanese eco-friendly tea

overall health rewards of eco-friendly tea

eco-friendly tea aspect outcomes

is eco-friendly tea fantastic for you

eco-friendly tea overall health rewards

eco-friendly tea tablets

what is eco-friendly tea fantastic for

positive aspects of eco-friendly tea

jasmine eco-friendly tea

eco-friendly tea dietary supplements

eco-friendly tea capsules

chinese eco-friendly tea

aspect outcomes of eco-friendly tea

eco-friendly tea excess fat burner

eco-friendly tea positive aspects

eco-friendly tea extract excess weight reduction

eco-friendly tea extract rewards

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.