14 Years Manufacturer Stevia Extract Factory in India

14 Years Manufacturer Stevia Extract Factory in India Detail:

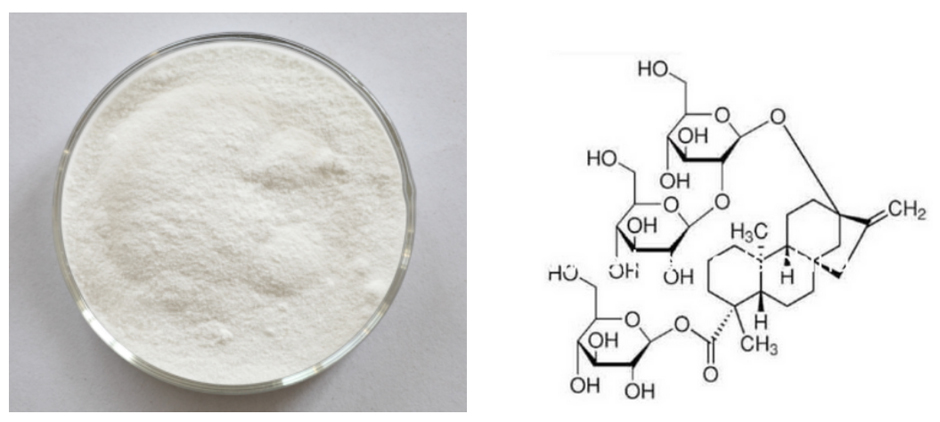

[Latin Name] Stevia rebaudiana

[Plant Source]from China

[Specifications] 1.Stevia Extract Powder (Steviosides)

Total Steviol Glycosides 80%, 90%, 95%

2. Rebaudioside-A

Rebaudioside-A 40%, 60%, 80%, 90%, 95%, 98%

3. Stevioside 90%

One monomer in Steviol Glycosides

[Appearance] Fine white powder

Plant Part Used:Leaf

[Particle size] 80 Mesh

[Loss on drying] ≤5.0%

[Heavy Metal] ≤10PPM

[Shelf life] 24 Months

[Package] Packed in paper-drums and two plastic-bags inside.

[Net weight] 25kgs/drum

Stevia Extract

[Characteristics]

Stevia sugar features high sweetness and low calorie and its sweetness is 200 350 times of that of cane sugar but its calorie is only 1/300 of that of cane sugar.

The component of stevia extract that gives it its sweetness is a mixture of various steviol glycosides. The components of sweetness in stevia leaves are stevioside, rebaudioside A, C, D, E and dulcoside A. Rebaudioside C, D, E and dulcoside A are small in quantity. The principal components are stevioside and rebaudioside A.

The quality of stevioside and rebaudiosideA is better than those of other components, which are commercially extracted and used in various applications.

The steviol glycosides present in stevia extract are referred to as “steviosides” or ¡°stevia extract¡±. Among these “steviosides”, the most common is Stevioside followed by RebaudiosideA. The Stevioside has a slight and pleasant herbal taste and the Rebaudioside-A has no herbal taste.

Although Rebaudioside C and dulcoside A are small in quantity in stevia extract, they are the major components giving bitter aftertaste.

[Function]

A large number of pharmaceutical tests have proved that stevia sugar has no side effects, carcinogens, and is safe for eating.

Compared with cane sugar, it can save 70% of the cost. With pure white color, pleasing taste and no peculiar smell, Stevia sugar is a new sugar source with broad perspective for development. Stevia rebaudianum sugar is the natural low hotsweet agent mostly similar to the flavor of cane sugar, approved to be used by State Ministry of Health and Ministry of Light Industry.

It is the third natural succedaneum of cane sugar and beet sugar with development and health care value, extracted from the leaves of the herbal vegetable of the composite family-stevia rebaudianum.

Product detail pictures:

Related Product Guide:

Our personnel are always in the spirit of "continuous improvement and excellence", and together with the top-quality good quality solutions, favorable selling price and superior after-sales providers, we try to acquire each customer's rely on for 14 Years Manufacturer Stevia Extract Factory in India , The product will supply to all over the world, such as: Auckland, Peru, Kazakhstan, Our tenet is "integrity first, quality best". Now we have confidence in providing you with excellent service and ideal merchandise. We sincerely hope we can establish win-win business cooperation with you in the future!

https://etop10christmas.com/free-ebook-for-losing-10-pounds

The Review of Raspberry Ketone :

@@@@@@@@@@@@@@@@@@@@@@@@@@@@

Raspberry ketone is an aromatic component present in raspberries and other fruits. It can also be produced synthetically in a lab.

Raspberry ketone, additionally accepted bargain as Rasketone, and Frambinone Rheosmin is a phenolic admixture that is abounding in red raspberries. He persuades the anatomy to absolution a hormone alleged norepinephrine. Additionally alleged accent hormone, norepinephrine affects that allotment of the brain, which controls anon for affliction and answers. By accretion the assembly of B beef and T, Raspberry Ketone weight loss also plays an important role in deepening the allowed system. In addition, it nourishes the anatomy with micronutrients such as vitamin B, vitamin C, iron, copper, manganese and magnesium.

https://etop10christmas.com/free-ebook-for-losing-10-pounds

Raspberry ketones reviews have shown that they are basically enzymes that have been extracted from the actual fruits. Many centuries ago, hunter and gatherer societies depended on raspberries for health purposes because even they were aware of the many healing properties that are naturally enveloped within each and every berry. Over time, millions of people just started to take raspberries and eat them because they knew that, like other fruits, there was a wide range of health benefits that could be experienced by consuming them.

Why has raspberry ketone been targeted for weight loss?

The Raspberry Ketone Reivews indicated that Scientists had previously shown that pungent compounds with similar chemical structures, such as capsaicin and synephrine, had lipolytic activity — causing fat breakdown — in rats fed a high-fat diet and in in vitro fat cells.

Raspberry ketone is not found in nature abundantly. So, raspberry ketone can be prepared industrially by a variety of methods from chemical intermediates. Like raspberry ketone can be prepared through a crossed aldol catalytic hydrogenation. In acetone and sodium hydroxide, 4 hydroxybenzaldehyde can form α, β unsaturated ketone. This then goes through catalytic hydrogenation to produce raspberry ketone. This method produces a 99% yield.

Raspberry ketones reviews have shown that they are basically enzymes that have been extracted from the actual fruits. Many centuries ago, hunter and gatherer societies depended on raspberries for health purposes because even they were aware of the many healing properties that are naturally enveloped within each and every berry. Over time, millions of people just started to take raspberries and eat them because they knew that, like other fruits, there was a wide range of health benefits that could be experienced by consuming them.

https://etop10christmas.com/free-ebook-for-losing-10-pounds

Raspberry ketone reviews reveals many great benefits of taking raspberry ketone supplement, but you can’t eat thousand of pills everyday, because the recommended daily dosage is 200 mg per day.

Get your FREE BOTTLE here: https://etop10christmas.com/free-ebook-for-losing-10-pounds

related search terms:

Raspberry ketones

Raspberry ketone

Raspberry reviews

Raspberry testimonials

Raspberry ketones side effects

Raspberry ketones before and after

Raspberry ketones reviews discover fastest

Flawless raspberry ketone

Raspberry for teens

Youtube raspberry ketone

Buy dr oz show raspberry ketone fat loss

Organic fat burner dr. oz

Fast belly loss gnc

100% pure raspberry ketones

Raspberry ketones drops

Raspberry ketone after results

Does raspberry ketone work

Raspberry ketone 500

Best supplement 800

Where to get raspberry ketone

Weight loss youtube

Lean raspberry ketone

The raspberry ketones

After results

Raspberries

Original raspberry ketone

Official raspberry ketones supplier

Raspberry ketone diets

Side effects video

Gnc raspberry ketone extract

Walmart raspberry ketones

Liquid 900 formula

Purchase ketones gnc

Extract of raspberry ketone

Dieting with raspberry ketone

As seen on tv

Ketone dr oz phone

Raspberry ketone brands that work

Ketone thin

Youtube raspberry ketone

Where to get raspberry ketone los angeles California

Best organic raspberry ketones

Ketone of raspberry

Fat burner raspberry ketone dr oz

Doctor oz recommended raspberry ketones

Best fat loss supplement

Mayo clinic raspberry ketones

Blame Technology 1999. BT7

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!