13 Years Factory wholesale Citrus Aurantium Extract Factory from Gambia

13 Years Factory wholesale Citrus Aurantium Extract Factory from Gambia Detail:

[Latin Name] Citrus aurantium L.

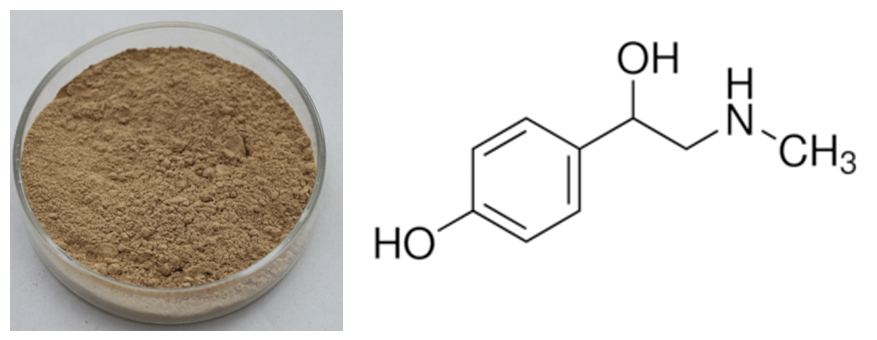

[Specification] Synephrine 4.0%–80%

[Appearance] Yellow brown powder

Plant Part Used: Fruit

[Particle size] 80Mesh

[Loss on drying] ≤5.0%

[Heavy Metal] ≤10PPM

[Storage] Store in cool & dry area, keep away from the direct light and heat.

[Shelf life] 24 Months

[Package] Packed in paper-drums and two plastic-bags inside.

[Net weight] 25kgs/drum

[What is Citrus Aurantium]

Citrus aurantium L, belonging to the family Rutaceae, is widely distributed in China. Zhishi, the Chinese traditional name for Citrus aurantium, has long been a folk medicine in traditional Chinese medicine (TCMto improve indigestion and help stimulate the Qi (energy force).

[Function]

1. Have the function of antioxidant, anti-inflammatory, hypolipidemic, vasoprotective and anticarcinogenic and cholesterol lowering actions.

2. Have the function of inhibiting following enzymes: Phospholipase A2, lipoxygenase, HMG-CoA reductase and cyclo-oxygenase.

3. Have the function of improving the health of capillaries by reducing the capillary permeability.

4. Have the function of reducing hay fever and other allergic conditions by inhibiting the release of histamine from mast cells. The possible activity of hesperidin could be explained by the inhibition of polyamine synthesis. (bitter orange extract)

Product detail pictures:

Related Product Guide:

Our commission is always to provide our customers and clientele with best quality and aggressive portable digital products for 13 Years Factory wholesale Citrus Aurantium Extract Factory from Gambia , The product will supply to all over the world, such as: Lithuania, Cannes, United Arab emirates, Our products are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is "to continue to earn your loyalty by dedicating our efforts to the constant improvement of our items and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate".

While at my dental check up appointment yesterday, upon comparing my gum line measurements from three years ago, my hygienist commented how my gums are much healthier than they had previously been. I told her I relate it to the health benefits of our OPC-3, a powerful antioxidant and anti-inflammatory supplement. (And my new electric toothbrush ![]() )

)

She was so impressed she has ordered a bottle to try for herself!

https://bit.ly/1EhJXQH

“In Search of the (Membrane) Holy Grail: A 20-Year Journey”

Mark Benjamin

Civil and Environmental Engineering, University of Washington

ABSTRACT: Natural organic matter (NOM) is universally recognized as a major foulant of membranes used for drinking water treatment. The fouling has been attributed to adsorption of NOM in membrane pores and/or to formation of a gel layer that covers the membrane surface. Colloids, humics, and polysaccharides have each been implicated as major contributors to this fouling material. Most efforts to reduce the impact of this fouling have focused on pretreatment with conventional coagulants or powdered activated carbon.

We have developed a new micron-sized, granular adsorbent by mild heating of aluminum hydroxide and demonstrated that it can adsorb NOM rapidly and more efficiently than conventional additives. In addition, a cake layer of the new adsorbent imposes very little hydraulic resistance. As a result, when these adsorbents are used as the media for precoat filtration, a substantial portion of the NOM can be removed from the feed with only a few seconds of contact time, thereby reducing DBP formation potential and also dramatically reducing the fouling of downstream membranes. Our recent research has focused identifying the chemical characteristics of the fouling fraction of the NOM, on ways to efficiently backwash the adsorbents off of the support material after their capacity to collect the contaminants has been exhausted, and on regeneration of adsorbent.

At virtually every step in the research, we have encountered unexpected and challenging issues, many of which we have overcome, but others of which we continue to struggle with. The presentation will provide an overview of the successes, the frustrations, and the excitement we still feel about the potential of this new process.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.