10 Years Manufacturer Bilberry extract Supply to Mali

10 Years Manufacturer Bilberry extract Supply to Mali Detail:

[Latin Name] Vaccinium myrtillus l.

[Plant Source] Wild bilberry fruit cultivated from Sweden & Finland

[Specifications]

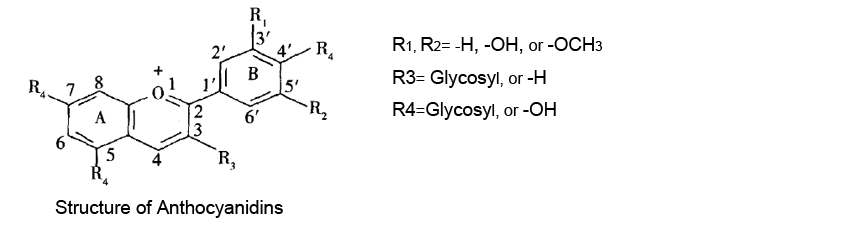

1) Anthocyanidins 25% UV (Glycosyl removed)

2) Anthocyanins 25% HPLC

3) Anthocyanins 36% HPLC

[Particle size] 80 Mesh

[Loss on drying] ≤5.0%

[Heavy Metal] ≤10PPM

[Pesticide residue] EC396-2005, USP 34, EP 8.0, FDA

[Storage] Store in cool & dry area, keep away from the direct light and heat.

[Package] Packed in paper-drums and two plastic-bags inside.

[General feature]

1. 100% extracted from European bilberry fruit, approved ID test from ChromaDex andAlkemist Lab;

2.Without any adultery of other relative species of Berries,such as Blueberry, Mulberry,Cranberry,etc;

3. Pesticide residue: EC396-2005, USP 34, EP 8.0, FDA

4. Directly import the frozen fruit from North Europe;

5. Perfect water solubility,water insolubles<1.0%

6. Chromatographic fingerprint match EP6 requirement

[What is bilberry fruit]

Bilberry (Vaccinium Myrtillus L.) is a kind of perennial deciduous or evergreen fruit shrubs, mainly found in subarctic regions of the world as in Sweden, Finland and Ukraine, etc. Bilberries contain dense levels of anthocyanin pigments, which was said popularly to have been used by World War II RAF pilots to sharpen night vision. In fork medicine, Europeans have been taking bilberry for a hundred years. Bilberry extracts entered the healthcare market as a kind of dietary supplement for effects on vision enhancement and visual fatigue relief.

[Function]

Protect and regenerate rhodopsin and cure the eye diseases;

Prevent the cardiovascular diseases

Antioxidant and anti-aging

Softening blood capillary, enhancing the heart function and resisting cancer

Product detail pictures:

Related Product Guide:

We persist with the principle of "quality 1st, assistance initially, continual improvement and innovation to meet the customers" for your management and "zero defect, zero complaints" as the standard objective. To great our service, we present the products and solutions while using the very good top quality at the reasonable cost for 10 Years Manufacturer Bilberry extract Supply to Mali , The product will supply to all over the world, such as: USA, Chicago, Germany, Now we have a excellent team supplying specialist service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We have been sincerely looking forward to cooperate with customers all over the world. We believe we can satisfy with you. We also warmly welcome customers to visit our company and purchase our solutions.

Why wait Order now :

https://myrainoffice.com/enroll/self_enroll_pc.php?sponsor=125969

Information :

www.rainsoul2u.com

call & delivery +6013-373 0101

https://www.myrainlife.com/johnnylee

https://www.facebook.com/rainsoul2u

What is Rain Soul ?

Rain Soul Powerful Antioxidants & Essential Fatty Acids to energize, revitalize, detoxify your mind, body & soul. Black cumin seed, Black raspberry seed, Grape seed, Ribose-D, Resveratrol.

富 含 抗 氧 化, 人 体 内 必 需 脂 肪 酸, 帮 助 人 脑 和 身 体 排 毒. 古 书 记 载 黑 小 茴 香 除 了 无 法 起 死 回 生, 种 籽 可 做 为 每 种 疾 病 的 治 疗 药 物.

Dr Otto Heinrich Warburg (Germany)

Nobel Prize in Medicine 1931 : Biochemist

The body requires special fats that, among other important functions. make it possible for sufficient oxygen to reach the cells via the cellular membranes. Which are the key, These special fats are highly oxygen-absorbing. Called Essential Fatty Acids, or EFAs, these special fats must be supplied from outside the body every day.

Black raspberry seed :

Contain antioxidant-like phytonutrients including ellagitannins and anthocyanins. These may help fight viruses, inflammation, and a number of other serious health conditions. Antioxidants seek out and eliminate cell-damaging substances, called free radicals. Free radicals can occur naturally in the body or from exposure to environmental toxins. Although ellagitannins exist in most berries, raspberries contain the the most potent levels.

Black raspberry seed :

Contain antioxidant-like phytonutrients including ellagitannins and anthocyanins. These may help fight viruses, inflammation, and a number of other serious health conditions. Antioxidants seek out and eliminate cell-damaging substances, called free radicals. Free radicals can occur naturally in the body or from exposure to environmental toxins. Although ellagitannins exist in most berries, raspberries contain the the most potent levels.

Grape seed :

Grape seeds have an abundant source of flavonoids called proanthocyanidins. This is important for brain health due to their free radical-quenching antioxidant and collagen-protecting effects. Proanthocyanidins have also been shown to noticeably delay the onset of lipid peroxidation and to effectively chelate iron ions. Free iron ions are some of the most powerful promoters of lipid peroxide, hydrogen peroxide and hydroxyl radical production. This is a major contributor to the pathogenesis of Parkinsons disease, one of the most common neurological diseases in older individuals.

Ribose-D :

Ribose-D is a five-carbon sugar found in every cell in our bodies that combines with oxygen and ATP (adenosine triphoshate) to give energy to each cell. Ribose is also present in RNA (ribonucleic acid), which is one of the main information carriers of living organisms. Oxidative stress, as measured by free radical damage to cells, leads to systematic inflammation. Fortunately, our bodies handle this problem daily. However, if our bodies experience an abnormal increase in free radicals due to exercise, daily stress, excess smoking, excess saturated fat intake, depressed immune system, aging, etc., the body becomes fatigued and less efficient in producing Ribose-D to replenish cellular energy. Because of this, we need to supplement with Ribose-D in order to regenerate the cells energy system.

Grape Extracts Resveratrol :

Grape skin extract contains trans-resveratrol which is considered a natural antibiotic that can fight bacterial diseases. Resveratrol may help protect the body from various diseases and slowing down the aging process.

BUY NOW RAIN SOUL :

Rain International . rain soul Asia . rain soul North America . rain soul Canada . rain soul United States . rain soul USA . rain soul Europe . rain soul Germany . rain soul United Kingdom . rain soul Croatia . rain soul Hungary . rain soul Romania . rain soul Serbia . rain soul Slovakia . rain soul Asia . rain soul China . rain soul Hong Kong . rain soul Indonesia . rain soul Japan . rain soul Malaysia . rain soul Philippines . rain soul Singapore . rain soul Brunei . rain soul Taiwan . rain soul Thailand . rain soul Shanghai

BUY NOW RAIN CORE :

Rain International . rain core Asia . rain core North America . rain core Canada . rain core United States . rain core USA . rain core Europe . rain core Germany . rain core United Kingdom . rain core Croatia . rain core Hungary . rain core Romania . rain core Serbia . rain core Slovakia . rain core Asia . rain core China . rain core Hong Kong . rain core Indonesia . rain core Japan . rain core Malaysia . rain core Philippines . rain core Singapore . rain core Brunei . rain core Taiwan . rain core Thailand . rain core Shanghai

How to order rain soul . how to buy rain soul . buy rain soul . rain nutrition . rain soul how to buy . be a rain soul distributor .

God is Good & Great…!!!

Jesus Bless You & Love You…!!!

CLEAR AND SIMPLE- Understand the similarities and differences between prokaryotic and eukaryotic cells. Find more free tutorials, videos and readings for the science classroom at ricochetscience.com

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!